Machinery

Topic outline

-

Conformity assessment procedures

The conformity assessment procedure is the procedure that the manufacturer must carry out to assess the conformity of the machinery with the applicable requirements of the Machinery Decree. In practice, the difference to the manufacturer is whether the Machinery Decree requires the use of a notified body for the assessment, or whether the manufacturer’s own measures are sufficient. The machinery’s importer must ensure that the manufacturer has applied the correct assessment procedure, i.e. that the machinery has been lawfully placed on the market. The distributor should also check this.

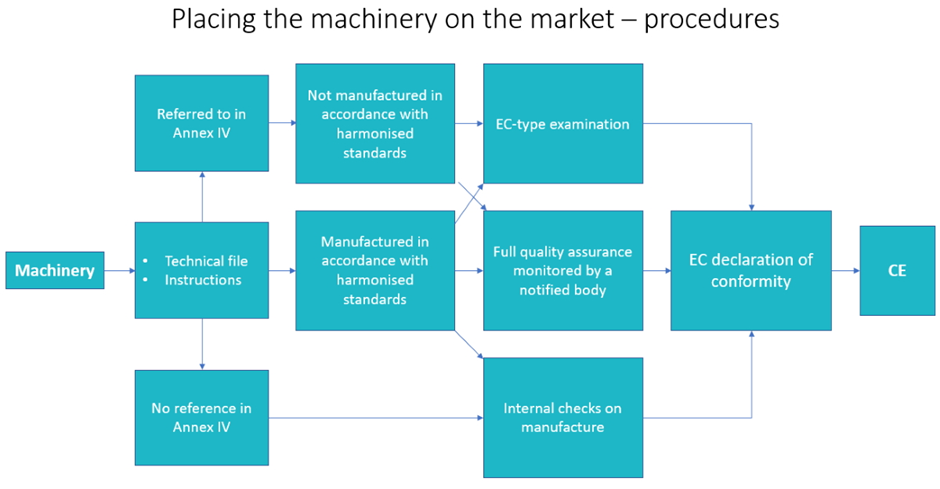

Below is a simplified flowchart of procedures to bring the machinery into conformity.

Placing the machinery on the market – procedures

Internal checks

The majority of the machinery intended for consumer use is placed on the market by applying the procedure for assessment of conformity with internal checks on the manufacture. In the case of internal checks, the manufacturer itself ensures that the machinery complies with the relevant requirements. This procedure does not require the participation of a notified assessment body or other external party. However, it can often be difficult in practice for a manufacturer to ensure that safety requirements are met without standardised testing at a test facility.

Assessment of conformity with internal checks is described in more detail in annex VIII of the Machinery Decree.

Machinery in annex IV

There are more stringent requirements for conformity assessment procedures for certain categories of machinery. In the case of machinery intended for consumers, examples of these machinery include chainsaws and vehicle lifts. All these categories of machinery are listed in annex IV of the Machinery Decree.

For machinery covered by annex IV, the manufacturer may choose between three different conformity assessment procedures.

1. Where machinery is manufactured in accordance with the harmonised standards, and these standards cover all the relevant essential health and safety requirements, the manufacturer may apply procedure of internal checks.

2. Where the machinery has not been manufactured or has been manufactured only partially, in accordance with the harmonised standards, or where the harmonised standards do not cover all the relevant essential health and safety requirements, or where no harmonised standards exist for the machinery concerned, the manufacturer must involve the notified body in the procedure. In such cases, the manufacturer may choose

a. EC-type examination of the machinery by a notified body or

b. apply a full quality assurance procedure

Notified bodies

The notified bodies are laboratories specialising in testing a type of product, and an EU member state has notified the Commission of it. Only these notified bodies are authorised to carry out conformity assessment tasks.

The notified bodies can be found in the NANDO database maintained by the European Commission: EUROPA – European Commission – Growth – Regulatory policy – NANDO You should note to which legislation (e.g. Machinery Directive), product group (e.g. vehicle lifts) and assessment procedure (e.g. EC-type examination) the notified body relates.

EC-type examination and EC-type examination certificate

EC-type examination is a procedure whereby a notified body ascertains and certifies that a machine of the type listed in annex IV meets the requirements of the Machinery Decree. Machinery other than those listed in annex IV cannot be subject to an EC-type examination in accordance with the Machinery Decree.

In this procedure, the manufacturer submits an application for an EC-type examination to a notified body of their choice. The application must contain the name and address of the manufacturer (and where appropriate, of their authorised representative), a written declaration that the same application has not been submitted to any other notified body, and a technical file of the type of machinery covered by the application. In addition, the manufacturer must send the notified body a sample of the type of machinery.

Body notified under the EC-type examination procedure:

- checks the technical file, and that the type of machine has been manufactured in accordance with the technical file

- specifies the parts that have been designed in accordance with the requirements of the harmonised standards, as well as those parts which have not been designed in accordance with the standards

- carries out or commissions the necessary examinations, measurements and tests to check whether the solutions adopted in the manufacture of the machinery meet the requirements of the Machinery Decree or Directive when the harmonised standards have not been applied

- when harmonised standards have been used, carries out or commissions the necessary examinations, measurements and tests to check that the standards were actually applied

- carries out or commissions the necessary examinations, measurements and tests to check that the type of machinery has been manufactured in conformity with the technical file

- if the type of machinery meets the requirements of the Machinery Decree or Directive, the notified body issues an EC-type examination certificate to the applicant. The certificate states the name and address of the machinery’s manufacturer (and where appropriate, of their authorised representative), the necessary identification data of the approved type of machinery, the conclusions of the examination, and the conditions under which the certificate was issued.

The certificate issued by the notified body must indicate the certificate’s date of expiry. It is the responsibility of the machine manufacturer to request a review of the certificate every five years to maintain its validity. Based on this review, the notified body shall decide whether to renew the certificate for a further period of five years.

Unlike the instructions and the EC declaration of conformity, the EC-type examination certificate does not need to be supplied with the machine. However, the EC declaration of conformity must include a reference to the type examination certificate where such a certificate applies to the machinery.

If the machine has undergone an EC-type examination, check the following in the certificate:

- the name of the certificate (EC-type examination certificate), i.e. that it is indeed the EC-type examination certificate

- which party issued the certificate, and that the party has the competence to issue certificates for the type of machine in question

- the identification data of the machine for which the certificate has been issued, and that it corresponds to the identification information of the machine itself

- the certificate’s period of validity, i.e. that it was and is valid when the machinery was or is placed on the market

How to indicate the applied procedure in the EC declaration of conformity

The applicable conformity assessment procedure must be indicated in the machinery’s EC declaration of conformity , so that if the machine has been EC-type examined, the declaration of conformity must contain the name and four-digit identification number of the notified body that carried out the type examination and the number of the type examination certificate. Where a full quality assurance procedure has been applied, the declaration of conformity must indicate the name and the four-digit identification number of the notified body which carried out the type examination.

You do not need to separately mention the procedure of internal checks in the declaration of conformity.

Read more about the EC declaration of conformity.

Remember:

- Check if your machine is listed in annex IV of the Machinery Decree

- If yes, please check which conformity assessment procedure has been applied

- conformity to standards

- EC-type examination/full quality assurance procedure

- check that the EC declaration of conformity contains an indication of the applied assessment procedure

- if the machine has been type-examined, check the contents of the certificate

Conformity assessment, testing and standards in practice

In many cases, the machinery must be tested with methods in accordance with machinery safety standards so that the manufacturer can ensure that the machinery meets the relevant safety requirements.

In turn, it may be impossible for the machinery’s importer or distributor to assess the conformity without test reports in accordance with machinery safety standards.

For testing purposes, it is essential to identify the standards for the device and any additional parts of the standards. The scope is mentioned at the beginning of the standard, which describes which products are covered by the standard. It is not always clear whether a product falls within the scope of a certain standard. In matters requiring interpretation, you can ask for help from standardisation organisations or accredited testing laboratories.

The machinery’s safety testing can be performed by the manufacturer or an external laboratory. In addition, the importer or distributor of the device can also test the device or have it tested if they want to ensure its safety. Testing machinery safety often requires knowledge of the standard and laboratory facilities and equipment, so the use of an external laboratory is often recommended. The use of an external accredited laboratory also increases the reliability of testing.

When selecting a testing laboratory, you should assess the laboratory’s competence to run tests. A national accreditation body (e.g. FINAS in Finland, SVEDAC in Sweden, DAkkS in Germany) can accredit a laboratory to carry out tests in accordance with a certain standard. The accredited laboratory has passed an impartial assessment.

You can check the accredited competence area of a laboratory operating in Finland on the website of FINAS accreditation service. You should check at least the following in the laboratory’s certificate of competence:

- Is the laboratory an accredited testing laboratory (letter T and number such as T004)

- Is the standard used within the scope of the laboratory?

You can also check the validity of the calibration laboratory on FINAS website if you need a calibration for an accurate measuring device (such as a production tester). In the calibration laboratory’s certificate of competence, you can check whether the laboratory has the competence to calibrate electrical quantities, weight, temperature, or humidity, for example. The calibration laboratory can be identified by a number sequence starting with the letter K.

Unaccredited testing and calibration are suitable for testing the product development phase, in-house calibration, or finding the right direction towards the final conformity assessment.

You should check the basic information from the testing, or the test report received from the manufacturer – for example, which device the report concerns, and whether the model of the device in question can be found in the report. The competence of the testing laboratory can be assessed as described above. In addition, the standard used for testing should be checked. Even if you do not know anything about the device itself or the related standards, you should check the following in the standard:

- Name of the standard

- Scope – to what kind of machines can the standard be applied?

- Is the version used for testing the latest version of the standard?

The EC declaration of conformity may refer to harmonised EN standards published in the Official Journal of the European Union. The Commission’s website contains a list of standards harmonised under the Machinery Directive (e.g. “summary list as PDF” at the bottom of the page). The two main points on the list are:

- Column 6: “date of start of presumption of conformity (1)” indicates the starting date since the standard could be referred to in the declaration of conformity.

- Column 11: “Date of withdrawal from OJ end of presumption of conformity (6)” shows the last date on which this version of the standard may be referred to in the EU declaration of conformity.

The use of standards is not mandatory but is often the easiest way to verify the conformity of a product.

When examining the EC declaration of conformity and test reports, it is important to note that this is the latest version of the standard, and that the amendments to the standard are included. The amendments may include stricter testing requirements, for example. On the other hand, a larger technical change in the standard will often lead to the publication of a completely new version of the standard.

You can buy Finnish SFS standards for machinery safety and SFS-EN standards from the website of the Finnish Standards Association SFS. More information on standards and standardisation is also available on the websites of METSTA and the National Electrotechnical Standardisation Organisation SESKO.

Watch a recording of Tukes’ I Know My Product webinar, Deep scan for machinery safety: reviewing the documents provided with the machinery: